Smart Solutions

for digitalization and reducing transportation costs

Trucknet provides a digital platform enabling companies to arrange shipments in all transport modes in order to reduce freight costs. Connecting to the platform can increase efficiency of supply chain processes by monitoring shipments from a single central place to ensure real-time visibility through location detection and status checks.

Sustainability

Connecting to Trucknet's automatic platform offers logistics and transportation companies opportunities for saving resources and cutting costs. In addition, the system delivers an online tool for heavy fleet companies to calculate their CO2 emissions. The heavy vehicle industry is expected to demonstrate social and environmental responsibility, and to comply with new EU standards for reducing CO2 emissions by 2030. Here is where Trucknet adds its unique solution. Quantifying greenhouse gas (GHG) emissions could provide possibilities for companies interested in carbon emission trading.

Efficiency

Trucknet can assist companies to apply their resources more effectively by selling unused space in trucks to other companies with information systems based on location. Our BID feature gives the best options available.

Extra profit

Companies gain extra profit by selling available capacity (empty space) to other transportation companies, thereby reducing deadhead miles.

Security

Trucknet's system adheres to the highest privacy standards, guided by GDPR (General Data Protection Regulation) requirements, and stores all data in an encrypted database. Security is the primary goal for the development team and the company is ISO 9001 and ISO 27001 certified.

Trucknet for outsourcing companies

(manufacturing companies, retailers, distributors, traders)

Benefits:

- Cost-saving generated by an automatic electronic bid system: save time and get the quickest and best cost option to organize your shipments;

- Pay less for your shipments by minimizing the cost of empty miles, using the automatic perfect match;

- Reduce all daily tasks of planners and communications (e-mail, phone) by a minimum of 50%;

- Decrease administrative costs for communication (phone), paper flow and printed documentation through digitalization of all relevant documents for each shipment;

- Increase KPI for delivery to your customers through Real Time Visibility.

Trucknet in a Nutshell

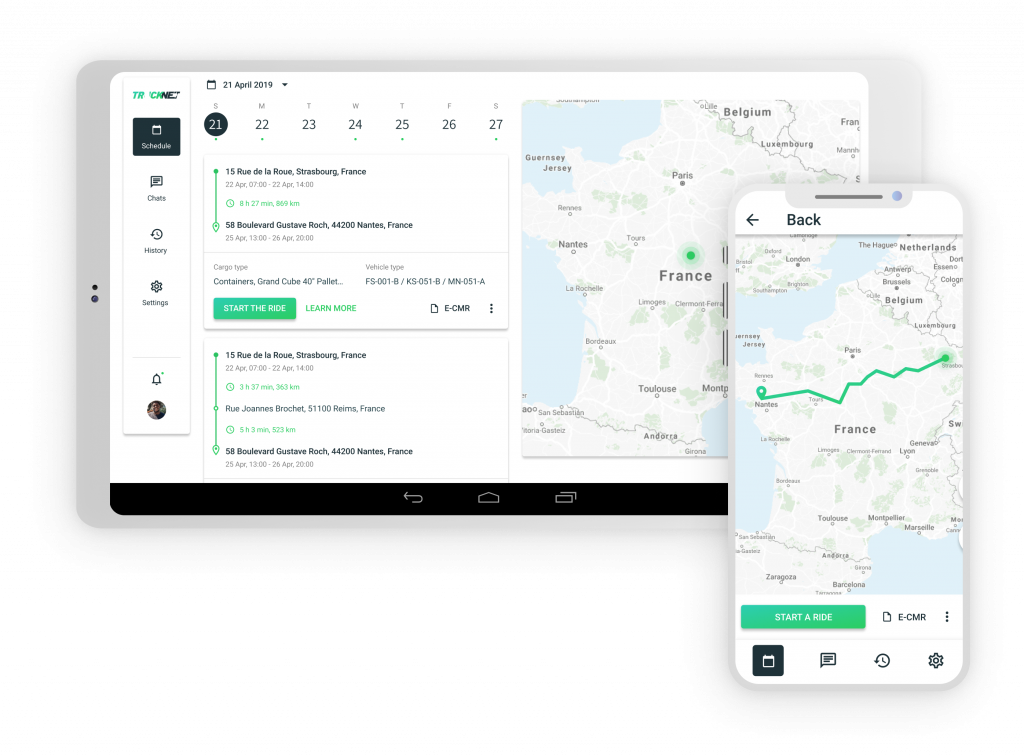

Easy to use

Manager Interface

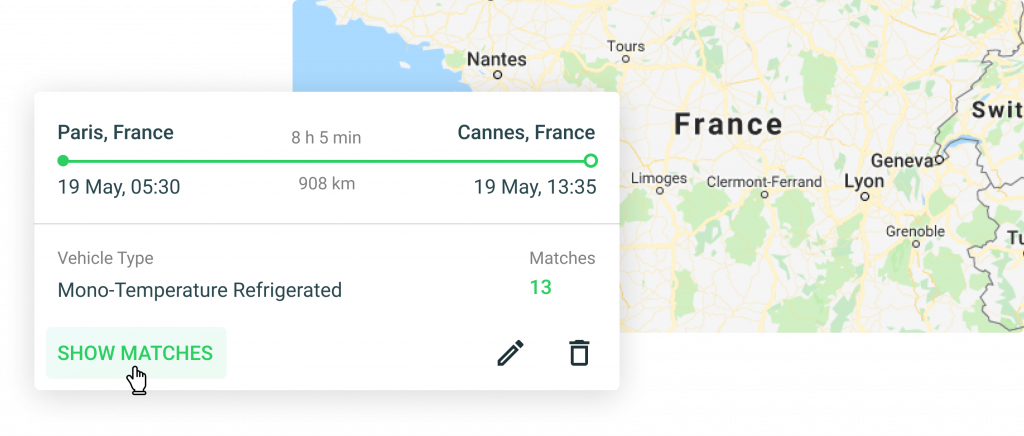

Web-based system

- Publish outsourcing requests and empty rides

- Search for outsourcing requests from other companies

- Manage schedules in Trucknet TMS (Roster)

- Create contracts between companies

- View the location of the outsourced truck

- Get an e-CMR document for any ride

- BID system

Partnerships

Our ESG Impact

SDGs

In 2015 United Nations Adopted the 2030 Agenda for sustainable development, which contains 17 Sustainable development goals (SDGs), each with its targets and indicators, representing an approach that organizations should work holistically to solve global sustainability challenges in various areas.

SDG 9

Industry, Innovation, and Infrastructure

Industry, Innovation, and Infrastructure

"Build resilient infrastructure, promote inclusive and sustainable industrialization, and foster innovation."

Read more...

SDG 8

Decent Work and Economic Growth

Decent Work and Economic Growth

"Promote sustained, inclusive and sustainable economic growth, full and productive employment and decent work for all."

Read more...

SDG 13

Climate action

Climate action

"Take urgent action to combat climate change

and its impacts."

Read more...

Try me!